What is LGP-STICKER?

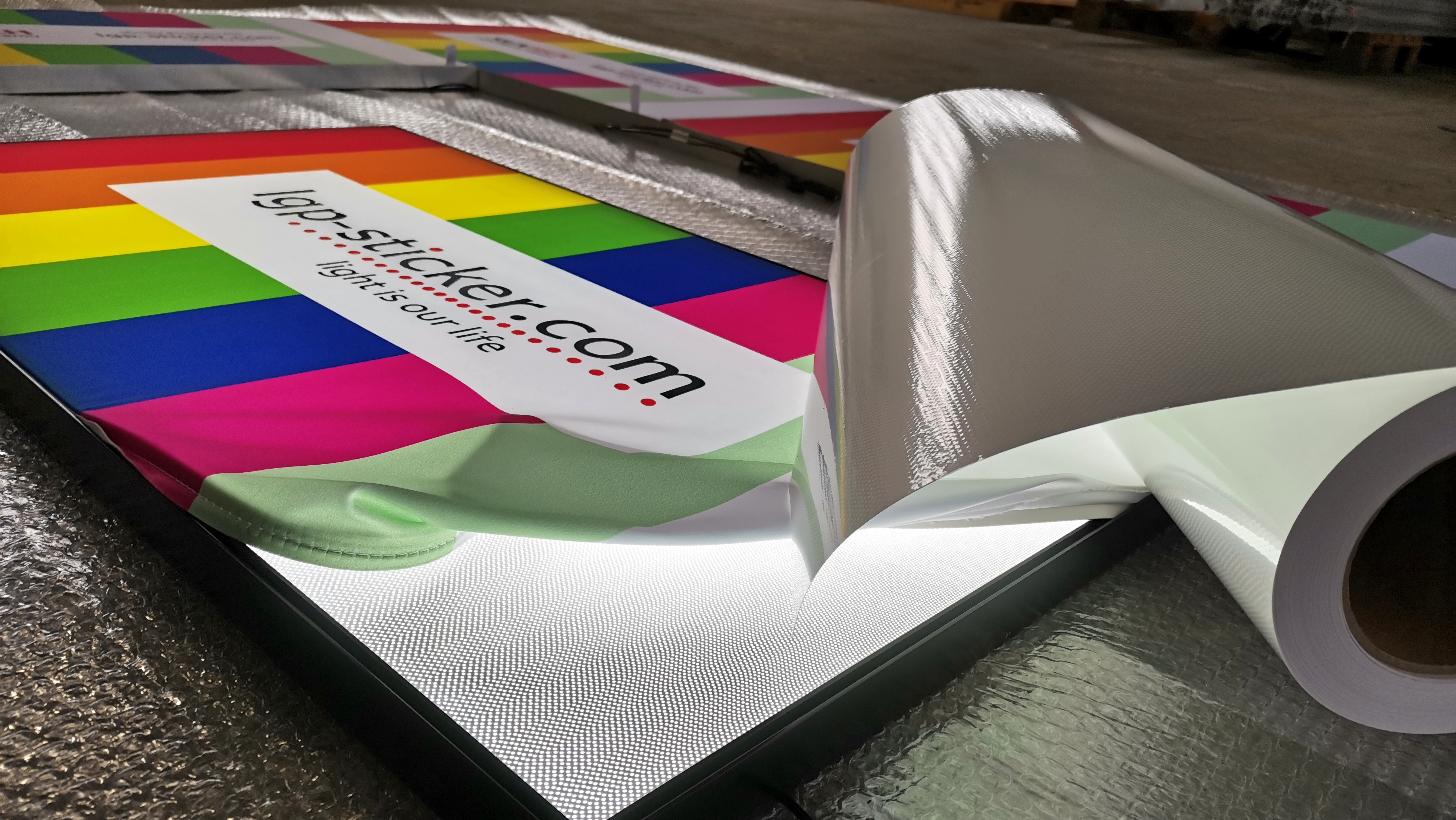

It is a reflective foil with a gradient formed from dots of glue. From the sides to the center of the film surface, the number of dots is densified evenly so that when illuminated into the edge of the acrylic glass, there is no visual loss of light across the desired panel area.

Preparation of acrylic glass for gluing LGP-STICKER

The better worked edge to which we shine the LED strip, the greater the resulting light effect. We recommend polishing the edge with a diamond polisher.

Similar light effect of the LGP panel can be achieved by laser cutting or flame polishing.

It is recommended to glue the edges that are not illuminated with reflective tape with as much light reflectivity as possible to return as much light back to the panel as possible. We use every lumen in this way.

We choose the right size of the LGP-STICKER foil so that it is as close as possible to the size of the acrylic glass plate.

Before gluing the LGP-STICKER foil, carefully clean the acrylic glass and remove any dust and dirt. We recommend working with gloves.

There are more ways of gluing and it is up to each signmaker to choose the technique (laminator, laminating table, roller, felt trowel, etc.).

ATTENTION!

If the LGP-STICKER foil is folded in any way during gluing, it may be visible after lighting. Neglected dirt is visible after lighting too.

BENEFITS of LGP-STICKER against competing LGP solutions

Thanks to LGP-STICKER, acrylic glass becomes a compact light source because the film is stuck directly on the acrylic glass surface.

Can be glued to any acrylic glass of any color and effect, up to a maximum width of 1500 mm.

The whole surface of the acrylic glass shines uniformly because the structure of the dots on the film is designed in such a way that for each given dimension the gradient of points is directly adapted to that particular dimension.

The foil does not contain PVC, which means it is environmentally friendly. LGP-STICKER can therefore be exported to Belgium too, and it is possible to produce products for customers who strictly care for the use of environmentally friendly materials.

Easy application. LGP-STICKER can stick anyone, it is bubble free.

LGP-STICKER is a biaxially oriented polyprophylene, does not stretch into the distance, which means that the LGP-Sticker practically cannot stick badly.

The acrylic glass covered with LGP-STICKER can be lit from one side (max width 750mm) or from two opposite sides (max width 1500mm).

FINANCIAL SAVINGS

LGP-STICKER is applied to normal acrylic glass of normal sizes and usually available on the market. It causes far less waste than a competing prefabricated LGP-Acrylic glass, and the entry price is reduced by 40-50%.

When processing acrylic glass by your laser from a normal to LGP, the entry price is reduced by 25-30%. At the same time, your laser can do a more valuable activity.

PACKAGING

LGP-STICKER is available in six widths: 300, 500, 610, 910, 1220 and 1500mm.

Rolls have a length of 50 meters.

The whole rolls are perfectly packed for transport into boxes of recycled honeycomb cardboard boards.

This protects the LGP Sticker film safely from possible harsh handling during transport.

When selling footage and incomplete rolls, we pack the material similarly gently so that it reaches the customer undamaged.